Resources

Resources to Elevate Your Skills

Why Test and Tag for Electrical equipment’s are important

Testing and tagging single-phase electrical appliances and equipment is crucial for several reasons, all

cantered around ensuring safety, compliance, and efficiency. Single-phase appliances are widely used

in various settings, including homes, offices, industrial environments, and public spaces. Below are

detailed reasons why testing and tagging these appliances is necessary:

1. Ensuring Electrical Safety

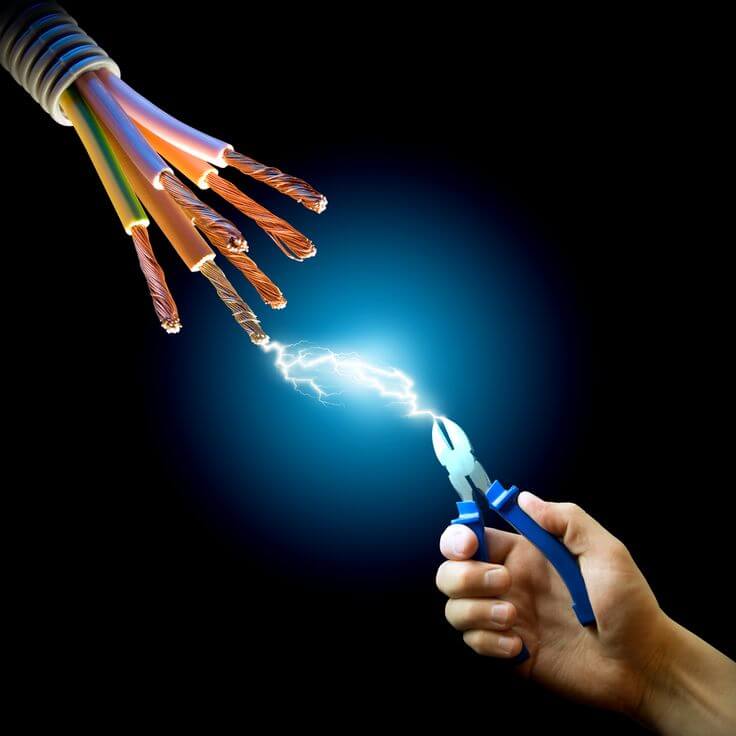

- Prevention of Electrical Shock: One of the primary reasons for testing single-phase appliances is to prevent electrical shock. Faulty appliances can have damaged insulation, exposed wires, or

malfunctioning components that could cause severe injury or even death if not detected and repaired. - Fire Hazard Prevention: Faulty electrical equipment is a significant fire risk. Overheating, short circuits, or sparks from malfunctioning appliances can easily ignite a fire. Regular testing helps identify and mitigate these risks before they lead to accidents.

2. Compliance with Legal and Regulatory Standards

- Occupational Health and Safety (OHS) Compliance: Many countries have strict regulations regarding electrical safety in the workplace. Regular testing and tagging ensure that businesses comply with these regulations, protecting them from legal liabilities and potential fines.

- Insurance Requirements: Many insurance policies require proof of regular testing and maintenance of electrical equipment. Failure to test and tag could result in a voided insurance policy, leaving the business unprotected in the event of an accident.

3. Maintaining Operational Efficiency

- Reducing Equipment Downtime: Regular testing helps identify potential issues before they result in equipment failure. By addressing these issues early, businesses can avoid unexpected downtime, which can be costly in terms of lost productivity and repairs.

- Prolonging Equipment Life:Regular maintenance through testing and tagging can extend the life of electrical equipment. Identifying and fixing minor issues before they escalate can prevent the need for costly replacements.

4. Protecting Employees and Customers

- Workplace Safety: Ensuring that all electrical equipment is safe to use protects employees from the risk of injury. This not only creates a safer working environment but also helps in maintaining employee morale and reducing absenteeism due to injuries.

- Customer Safety: In environments where customers interact with electrical equipment (e.g., retail stores, hotels, etc.), testing and tagging ensure that the equipment is safe for public use, thereby protecting the business’s reputation and preventing potential lawsuits.

5. Identification of Faulty Equipment

- Early Detection of Faults: Regular testing can identify faults that may not be pparent during normal operation. This includes issues like earth leakage, insulation resistance, and polarity problems, which can be dangerous if left unchecked.

- Isolation of Defective Appliances: Once a faulty appliance is identified, it can be tagged and removed from service until it is repaired or replaced. This process helps prevent the use of unsafe equipment.

6. Environmental Considerations

- Energy Efficiency: Testing can identify ppliances that are not operating efficiently, which may be onsuming more ower than necessary. Replacing or repairing these appliances can reduce energy consumption, leading to cost savings and a lower environmental impact.

- Waste Reduction: By maintaining equipment properly, businesses can reduce the need for premature replacements, contributing to waste reduction and more sustainable operations.

7. Legal Liability and Duty of Care

- Employer’s Duty of Care: Employers have a legal obligation to provide a safe working environment. Regular testing and tagging of single-phase electrical appliances is part of fulfilling this duty of care, ensuring that all equipment used in the workplace is safe.

- Minimizing Legal Risks: In the event of an accident caused by faulty electrical equipment, businesses that have not complied with testing and tagging requirements may face significantlegal challenges, including lawsuits, fines, and penalties.

8. Documentation and Traceability

- Record Keeping: Testing and tagging provide a documented history of the condition of electrical appliances. This documentation can be crucial during audits, inspections, or in the event of an incident, as it provides evidence that the business has taken all reasonable steps to ensure safety.

- Scheduled Maintenance: Tags often include the date of the last test and when the next test is due, helping businesses keep track of when each piece of equipment needs to be re-tested.

Conclusion

Testing and tagging single-phase electrical appliances and equipment is an essential practice for any

business or organization that uses electrical devices. It helps ensure the safety of employees and

customers, maintains compliance with legal requirements, protects against legal liabilities, and

contributes to the efficient and sustainable operation of equipment. Regular testing and tagging are not

just a regulatory obligation but a critical component of a comprehensive workplace safety and

maintenance strategy.

Test Tag for fire equipment-FAQ’S

As an employer, maintaining compliance with the Australian Standard – AS/NZS 3760 is crucial to protect your workplace from injuries and health hazards.

However, we understand that you may need more information about how we conduct our tests and why they are necessary.Below, you’ll find answers to some of our most frequently asked questions.

Test and tag is a process involving the testing of electrical equipment for safety and then tagging it

with a label to indicate its status. It ensures that electrical devices are safe to use and comply with

safety standards.

Testing and tagging help prevent electrical accidents, ensure compliance with safety regulations,

and maintain a safe working environment. It identifies faulty equipment before it can cause harm.

The frequency of testing and tagging depends on the type of equipment and its environment.

Generally, equipment used in high-risk environments (e.g., construction sites) needs more frequent

testing compared to equipment in low-risk areas (e.g., offices).

Only a qualified and competent person, such as a licensed electrician or a certified tester, should

perform test and tag procedures.

The testing process typically includes a visual inspection, electrical testing using a Portable

Appliance Tester (PAT), and checking for insulation resistance, earth continuity, and polarity.

The tag usually includes the test date, the next test due date, the name of the tester, and the

status of the equipment (e.g., passed or failed).

If equipment fails the test, it should be removed from service immediately and either repaired by a

qualified technician or disposed of if it cannot be safely repaired.

In many countries, test and tag are mandatory for workplaces to comply with occupational health

and safety regulations. Specific requirements vary by region and industry.

It is common for people to refer to the service as tag and test, however, the correct name is test and tag. The words ‘test and tag’ clearly outline the process of the service. First, we test the appliance and then follow by tagging it.

While it is possible to test and tag your own equipment if you have the necessary knowledge and

equipment, it is generally recommended to use a certified professional to ensure accuracy and

compliance with regulations.

Any electrical equipment that is plugged into a power source should be tested and tagged. This

includes items like power tools, computers, kitchen appliances, and extension cords.

Regular testing and tagging ensure compliance with safety standards, reduce the risk of electrical

accidents, increase the lifespan of equipment by identifying issues early, and provide peace of

mind for employers and employees.

When choosing a test and tag service provider, look for certification, experience, positive customer

reviews, and compliance with local regulations. It’s also beneficial to compare pricing and services

offered.

If you have any other questions about test and tag, feel free to contact us for more information.

If you have any other questions about test and tag, feel free to contact us for more information.

Need assistance?

Reach out to us today, or simply fill out the contact form to get in touch.